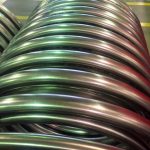

Milkcooler tubes

The client’s question

- I need to spiralize tubes throughout the whole year . These spirals are built in a milk cooler. We demand a very high, but even more important, a very constant bending quality of the inox tube.

- The tubes have to meet the highest hygiene standards (inner tolerance 0,80µm / 0,80µ).

- The tubes for these particular milk coolers are very long and can therefore not be stored at the constructor’s site.

- The standard delivery time for this type of tube, is normally about 12 weeks.

Versinox’s solution

We purchase one single coil of raw strip material, so only one batch of material is used for the complete project. We also book the necessary capacity on the tube welding machine for the complete duration of the project. This way, we are able to deliver the needed tubes on demand and on time.

Working like this, Versinox manages to deliver the tubes in 4 weeks maximum. The constructor can fully rely on the deliveries and barely has to keep stock himself.

Together with the client, we optimized the tube specifications, so they could be used better, faster and easier. Especially the tolerances on the inner and outer diameter and the internal roughness were quite tightened in relation to the original standards. This eventually results in less failures and stagnation during spiralizing.

Client’s benefits

- A constant bending quality

- Just-in-time deliveries, but especially on time!

- Almost no prefinance

- A perfect quality tube, so a longer lifespan of the milkcooler.

Share this: