Stainless tubes for heat exchangers; is what you asked for also delivered?

“It is stated in the standards, so it will probably be allright”

In our daily practice we see lots of misconceptions concerning specifications of heat exchanger tubes. Unfortunately, this is already the moment that things go wrong. Price is too often leading in the competition between constructors, while the end customer expects to get the requested quality delivered. It however makes quite a difference if (and how) stainless tubes are delivered according to the European EN10217 standard in comparison to the American ASTM A249 standard… Tubes that are not specified sufficiently, surely can lead to higher production and maintenance cost in the end. At Versinox we therefore advice to particularly consider Total Cost of Ownership and not only the initial purchase price.

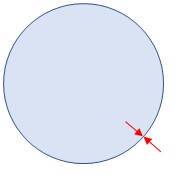

The weld seam on a welded stainless tube

With a welded stainless tube, our first question invariably is whether or not the tube is suited for its job. The European standard for heat exchanger tubes, the EN10217, does not specify if the tube should be annealed or not. It also leaves room whether or not to smoothen the inner weld seam. Both specifications are left to the user, but he should specify these explicitly! If only EN10217 is specified, he probably will be offered the cheapest option (not annealed or smoothened). The American ASTM-A249 does provide these specifications.

With a welded stainless tube, our first question invariably is whether or not the tube is suited for its job. The European standard for heat exchanger tubes, the EN10217, does not specify if the tube should be annealed or not. It also leaves room whether or not to smoothen the inner weld seam. Both specifications are left to the user, but he should specify these explicitly! If only EN10217 is specified, he probably will be offered the cheapest option (not annealed or smoothened). The American ASTM-A249 does provide these specifications.

Unannealed tubes are not always the best option though. The corrosion resistance of the weld seam is less, resulting in substantial risk of corrosion. Moreover, all modern tube production machines are equipped with annealing options. Unannealed tubes therefore often are derived from engrained machinery that deliver tubes of less quality and ditto weld seam. The end user must therefore know quite accurately what he needs to specify if he doesn’t want to be at risk with exchangers in which flow chemicals, flue gasses, oil and suchlike.

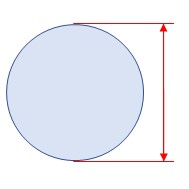

Tolerances on the outer diameter of the stainless tube.

The EN10217 also gives the user the possibility to choose a tolerance class that leaves lots of space in the execution of the tube. The ASTM standard (A249-A1016) however, states a standard tolerance for each size range. And every exchanger constructor knows that the more accurate the outer diameter is, the easier it is applied and the less tolerance and vibrations as a result. It is thus important to specify this clearly.

The EN10217 also gives the user the possibility to choose a tolerance class that leaves lots of space in the execution of the tube. The ASTM standard (A249-A1016) however, states a standard tolerance for each size range. And every exchanger constructor knows that the more accurate the outer diameter is, the easier it is applied and the less tolerance and vibrations as a result. It is thus important to specify this clearly.

Tolerances on wall thickness of the stainless tube

Due to its influence on the weight, the wall thickness of a tube is of eminent importance to the price of stainless tubes. Applying different standards often lead to “unexplainable” price differences originating from this factor. But the risk of a wall thickness too thin, applying the standards poorly, are lurking. A wall thickness too thin can lead to weakness, wear or faster corrosion.

Due to its influence on the weight, the wall thickness of a tube is of eminent importance to the price of stainless tubes. Applying different standards often lead to “unexplainable” price differences originating from this factor. But the risk of a wall thickness too thin, applying the standards poorly, are lurking. A wall thickness too thin can lead to weakness, wear or faster corrosion.

An example of how differences arise, applying different standards:

With ASTM, a tube size Ø 25 x 1 mm requires a tolerance of 10%, with a lower limit of 0,9 mm. With EN10219, tolerance class T3, this size tube requires a tolerance of +/-10% OR +/- 0,2 mm. So the lower limit can become 0,8 mm if not specified more strictly!

Tolerances on the length of the stainless tube

Finally, a constant length of the tubes is very desirable to construct heat exchangers for most constructors are surely not keen on grinding off the tubes to get equal lengths.

Finally, a constant length of the tubes is very desirable to construct heat exchangers for most constructors are surely not keen on grinding off the tubes to get equal lengths.

Another example of how different standards lead to substantial differences in length:

With ASTM, tubes of maximum size Ø 50,8 mm require a tolerance of -0+3 mm and -0+5 with tubes size > Ø 50,8 mm. So our example tube of Ø 25 x 1, length 8.000 mm can be delivered with a maximum size of 8.003 mm.

With the EN10217 standard, the length tolerance depends scalable on the length of the tube. The very same tube now has a tolerance of -0+10 mm. This means that the tubes can be delivered with a length of 8.010 mm!

So the pressing questing is what tubes you will get if you specify little or nothing at all… And pennywise can become pound foolish after all. Not sure if the standards you use come up to the true requirements? We are pleased to advice and help you out.

Share this: